Edge Collective

Off-grid, low-carbon DIY transport & cargo

Designs for bike trailers, wheelbarrows, etc.from crutches:

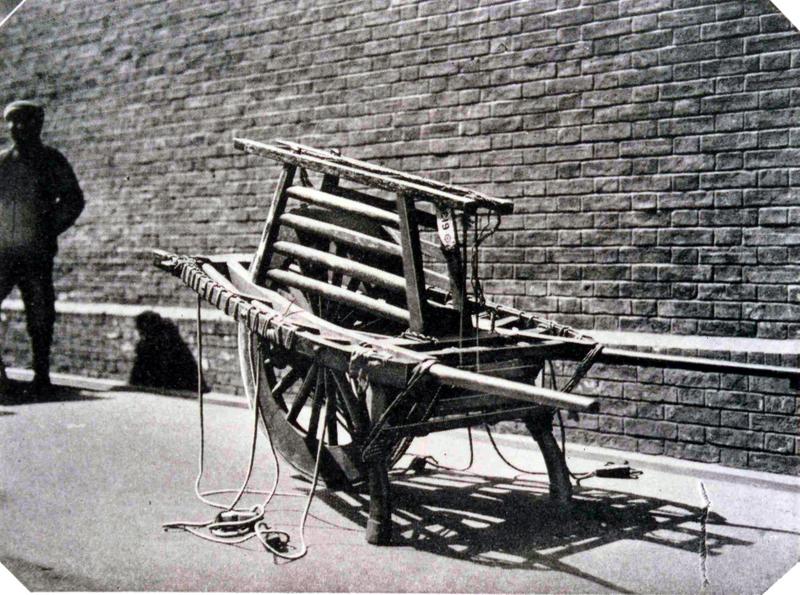

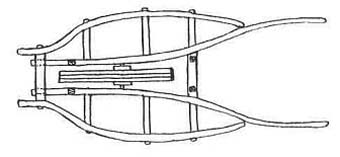

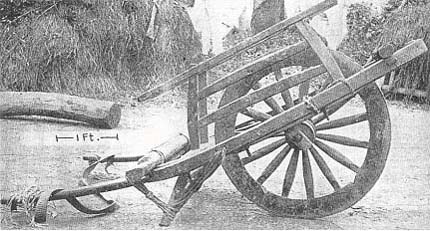

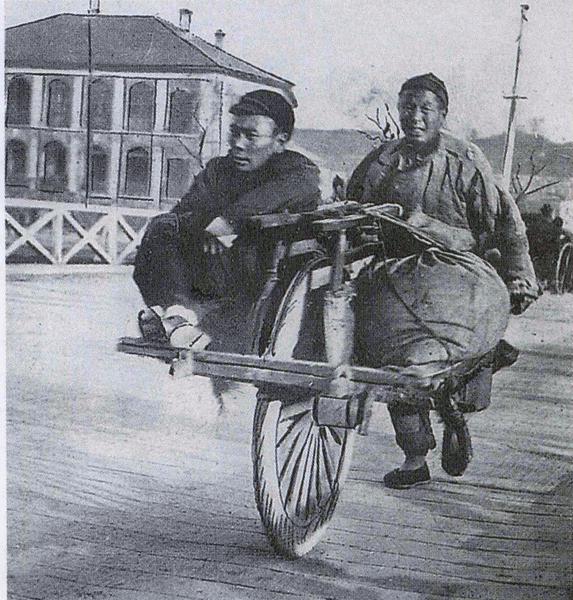

Chinese Wheelbarrow https://www.lowtechmagazine.com/2011/12/the-chinese-wheelbarrow.html

2021-09-09 21:37:06

No-weld bike trailer https://www.youtube.com/watch?v=kHwX_x-4SrQ

PVC bike trailer https://www.youtube.com/watch?v=QcxcH2UeamU

Wed Sep 13 06:03:59 PM EDT 2023

No-weld bike trailer designs:

Main reference, with nice design elements: http://drumbent.com/trailer.html

Version with plastic bin: http://drumbent.blogspot.com/2007/05/fan-mail-2.html

Larger trailer, with nice build pics:

http://drumbent.com/trailer_big.html

Hitch / coupler designs

Air hose couping: https://www.instructables.com/No-Weld-Bicycle-Trailer-Hitch/

No-weld bike trailer reference: https://www.instructables.com/No-Weld-Bike-Trailer/

Kayak-carrying bike trailer with nice spring hitch design:

Bike trailer hitch on Amazon: https://www.amazon.com/Connector-Childrens-Trailers-Accessories-Cenipar/dp/B0912XSCPK

Spring clip at home depot: https://www.homedepot.com/p/Everbilt-5-16-in-x-2-3-4-in-Zinc-Plated-Round-Wire-Lock-Pin-807488/204225915

E-bike conversion

Wirecutter article: https://www.nytimes.com/wirecutter/blog/build-ebike/

E-bike school: https://www.ebikeschool.com/

DIY Recumbents

Bike dropout design

https://www.jeffgeerling.com/blog/2021/how-export-2d-illustration-3d-model-openscad

Wed Oct 18 07:06:43 PM EDT 2023

https://gitlab.com/edgecollective/bike-trailer-dropouts/-/tree/main/v_0.1?ref_type=heads

Sun Oct 29 07:31:51 PM EDT 2023

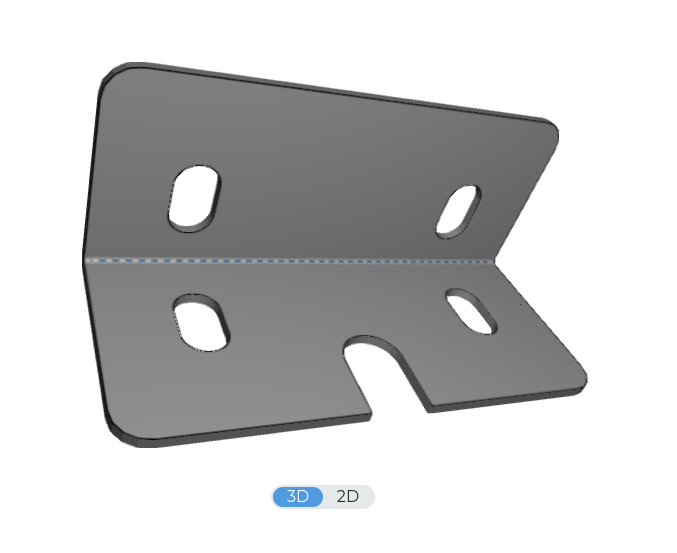

Adding a bend:

bike_plate_2_bend.dxf

Mon Oct 30 05:04:13 PM EDT 2023

Assembled initial trailer. Notes:

- internal dropouts need to be shifted up to account for geometry of support bars

- if u-bolts will be used, should be oriented sideways with bend to avoid bolts sticking out

i.e. can do 0.16" diameter hole i.e. 4 mm

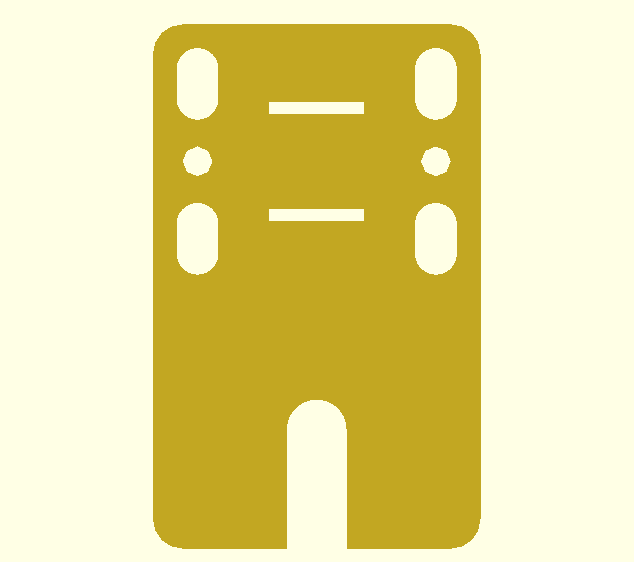

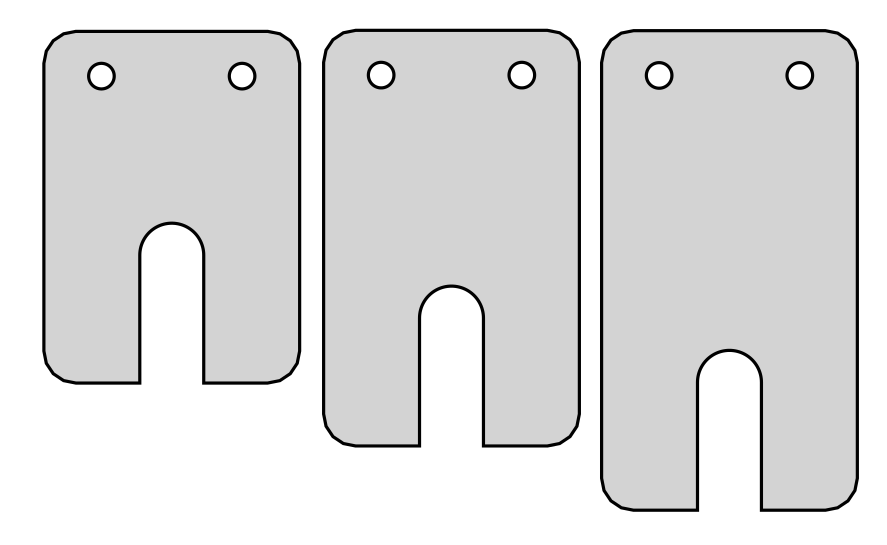

Trailer dropouts "Version 0.3"

Choosing 0.125" (3.2 mm) thickness this round.

Convention:

- 'short' is the one that is attached to the 'outer' frame

- 'middle' is inner frame, if use flattened ends; it is longer by 0.5 of pipe diam (1/2" EMT)

- 'long' is inner frame, if use non-flattened ends; it is longer by a pipe diam

Version 0.3 on github: https://gitlab.com/edgecollective/bike-trailer-dropouts/-/tree/f21a3fa739245bb51466d63d18eab6291da84101/v_0.3

Wed Nov 8 09:47:47 PM EST 2023

Trailer Version 1.0

- Dropouts need wider mounting holes, to accommodate a #10 screw (need to measure diameter precisely)

- Might want to select 'lock nuts' or similar

- Might want to upgrade bolt size for added strength

Do some experiments around lightweight 'beds' for the trailer. Wood tends to add unnecessary weight

Sun Nov 12 09:53:09 PM EST 2023

Regusci

Lots of details in this interview:

https://docs.google.com/document/d/1HWtfLdNdpZcJ-JoulyjzweFRW8-5IA9u-lwdERs4XhY/edit

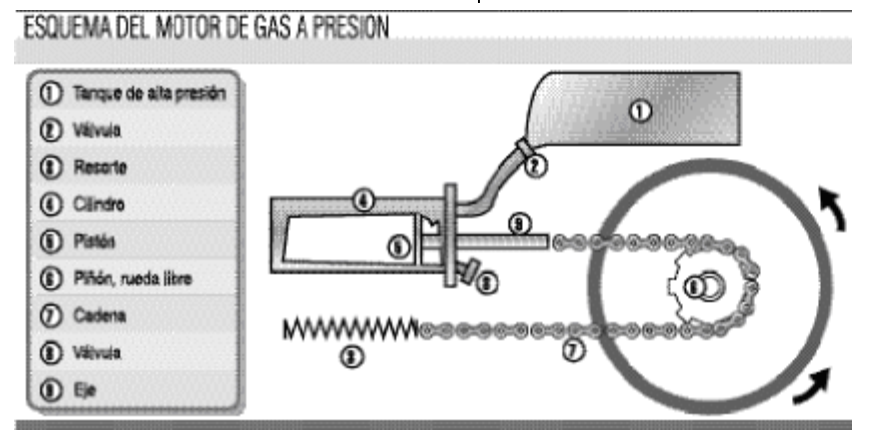

Including this diagram:

-

2" bore 12" stroke on amazon here

-

2.5" bore 20" stroke https://www.amazon.com/Baomain-Pneumatic-Cylinder-SC-Bore/dp/B0741CS8MK/ref=psdc_3021479011_t3_B072VQYT4S?th=1

academic article http://ijiird.com/wp-content/uploads/2017/05/010227-AIR-CAR-hybrid-vehicle.pdf

regusci report https://www.regusciair.com/informes

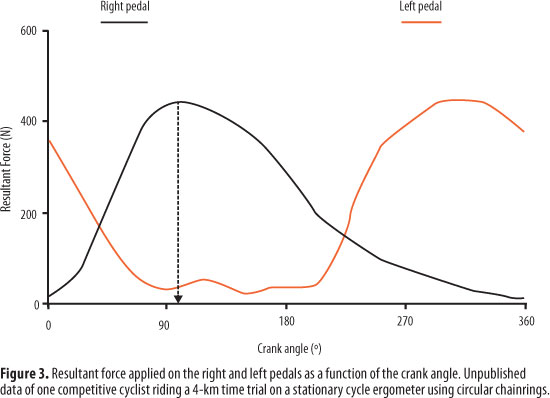

tensile forces on chain on bikes https://zerofrictioncycling.com.au/wp-content/uploads/2019/07/Chain-Tensile-Strength-Test-Brief-converted.pdf

pneumatic cylinder force calculator https://www.omnicalculator.com/physics/pneumatic-cylinder-force

torque in electric bikes https://www.himobikes.com/blogs/news/what-does-torque-mean-in-electric-bikes

basics of pneumatics / getting started https://www.youtube.com/watch?v=Uz9xXEXzkxQ

pneumatics 101 https://www.youtube.com/watch?v=ZccQVMtQd6k

controlling a pneumatic cylinder easily https://www.youtube.com/watch?v=dR95umuNSPY&t=54s

controlling a pneumatic cylinder with arduino https://www.youtube.com/watch?v=iXNNjtK5hp8&t=188s

how to operate a pneumatic cylinder from a co2 tank https://www.youtube.com/watch?v=wCxJ12s1-cI

Wed Nov 22 04:28:34 PM EST 2023

Different types of pneumatic cylinders

https://mechanicalengineering120.files.wordpress.com/2017/11/lecture-37_pneumatics-actuators.pdf

https://www.norgren.com/en/support/blog/why-choose-a-single-acting-cylinder

https://trimantec.com/blogs/t/difference-between-single-and-double-acting-pneumatic-cylinders

https://lehighfluidpower.com/wp-content/uploads/2018/09/38a-Spring_Article.pdf

Bicycle rear hubs

https://bike.bikegremlin.com/158/bicycle-rear-hub/

Dual chain assembly

https://endless-sphere.com/sphere/threads/using-two-drive-chains-to-one-hub-one-on-each-side.9586/

History of air powered bicycles

Getting started with pneumatics

https://www.youtube.com/watch?app=desktop&v=Uz9xXEXzkxQ

Control pneumatics with arduino

https://www.youtube.com/watch?v=iXNNjtK5hp8&t=190s

Modify a small fridge compressor into a silent air compressor

https://www.instructables.com/How-to-modify-a-fridge-compressor-into-a-silent-ai/

Extinguisher compressed air tank conversion

https://www.youtube.com/watch?v=-1QasBxF0z4

Old fire extinguisher for compressed air

https://www.youtube.com/watch?v=B0NY18IqCtU

Turn Fridge Compressor into Air Compressor

https://www.youtube.com/watch?v=0Kmyl8eWOBE

Calculaing Force from pneumatic cylinder

Thu Nov 23 09:29:49 PM EST 2023

Key moment in regusci video showing action of piston [https://youtu.be/dwdOLp4NqtY?t=26](https://youtu.be/dwdOLp4NqtY?t=26]

Need an average of 45 lbs to push a bicycle forward, according to https://physicalcycling.com/pedaling-force/#:~:text=Average%20Pedaling%20Force&text=Simulations%20can%20model%20these%20different,nwts%20or%20around%2045%20lbs.

Claims max of about 400 Newtons, or 90 lbs

This 2.5" bore 20" stroke piston should do the trick: https://www.amazon.com/Baomain-Pneumatic-Cylinder-SC-Bore/dp/B0741CS8MK/ref=psdc_3021479011_t3_B072VQYT4S?th=1 -- should give 1300 Newtons at 60 psi, or 700 Newtons at 30 psi

Great intro video: https://www.youtube.com/watch?app=desktop&v=Uz9xXEXzkxQ

Hand-operated solenoid with fittings (1/4" NPT) https://www.amazon.com/RIH-Operated-Pneumatic-Solenoid-4H210-08/dp/B0B7DV8SYD/ref=psdc_1265148011_t4_B01E6W65TM?th=1

Best-rated hand-operated https://www.amazon.com/Tailonz-Pneumatic-Position-Operated-4H210-08/dp/B07SHG911C/ref=psdc_1265148011_t1_B0B7DV8SYD?th=1

Looks like it is standardizing around 1/4" -- which is 6 mm

1/4" adjustible silencer on Amazon

looks like pt3/8 means that the port size is 3/8"

connecting 3/8" port to various tube sizes on amazon here

So: - piston has 3/8" fittings

- can convert this to whatever size

- solenoid can have various sizes

- tube can have various sizes

Note that piston has max 140 PSI

Looks like Craftsman 6 Gallon Pancake air compressor using 1/4" fittings

5 Gallon compressed air tank -- 120 PSI max

Tank end is 1/2" MNPT male

Better way to fill up a compressed air tank https://www.youtube.com/watch?v=Epeul6T0v8k

Modifying an 11 Gallon Harbor Freight air tank https://www.youtube.com/watch?v=Ta2I9-vB5OQ -- key video!! shows how to make connectors

Portable air tank budget upgrade https://www.youtube.com/watch?v=Sf8fwdKFumo

Unboxing of harbor freight tank https://www.youtube.com/watch?v=G7ExtBA_SaM

Sat Nov 25 06:13:46 PM EST 2023

modifying the tank https://www.youtube.com/watch?v=Sf8fwdKFumo

industrial quick coupler and plug set https://youtu.be/Sf8fwdKFumo?t=24

1/4 " male automotive coupler

3/8 " rubber air hose :w

modifying the hose https://youtu.be/Sf8fwdKFumo?t=32

filling the tank https://youtu.be/Sf8fwdKFumo?t=119

making the coupler to fill w/ compressed air https://youtu.be/Ta2I9-vB5OQ?t=168

3 way 2 position valve 1/4" NPT

crimping your own hose https://youtu.be/fUsdt9GH1rA?t=98

1/4 " barb fitting for air hose https://www.homedepot.com/p/Everbilt-1-4-in-Barb-x-1-4-in-MIP-Brass-Adapter-Fitting-800119/300096726

Making a PVC Pneumatic Cylinder

Wed Nov 29 08:12:16 PM EST 2023

Freewheels

Freewheel removal and installation

Mounting two freewheels on one rear hub

Demonstration, with pictures, here:

[https://endless-sphere.com/sphere/threads/mounting-two-freewheels-on-one-rear-wheel-hub.13862/](https://endless-sphere.com/sphere/threads/mounting-two-freewheels-on-one-rear-wheel-hub.13862/]

Related: replacing an older bottom bracket (one of the parts needed for the above approach?) https://www.youtube.com/watch?v=qGuIiPwKXck

Cogs for front wheel

https://bicycles.stackexchange.com/questions/54481/cogs-for-front-wheel

Using two drive chains to one hub

https://endless-sphere.com/sphere/threads/using-two-drive-chains-to-one-hub-one-on-each-side.9586/

Double RH freewheel hub design

https://endless-sphere.com/sphere/threads/double-rh-freewheel-hub-design.40661/

Considerations of Parallel Drive Setups

https://endless-sphere.com/sphere/threads/considerations-on-parallel-drive-set-ups.12449/

Delta trike with front wheel drive

https://www.instructables.com/Delta-Trike-with-Front-Wheel-Drive/

Trike differential

Dual Freewheel

Tandem Hub Double-Threaded

https://www.amazon.com/transformparts-Double-Threaded-Bicycle-Electric/dp/B07PV7PC42

Sat Dec 2 08:02:26 PM EST 2023

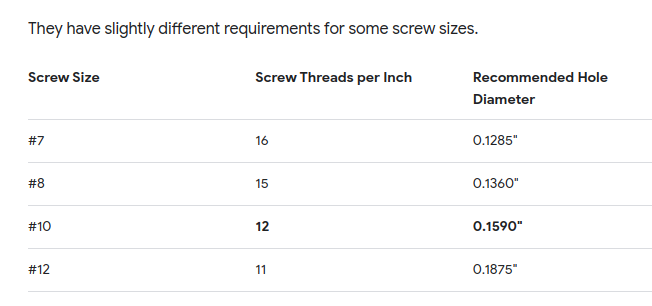

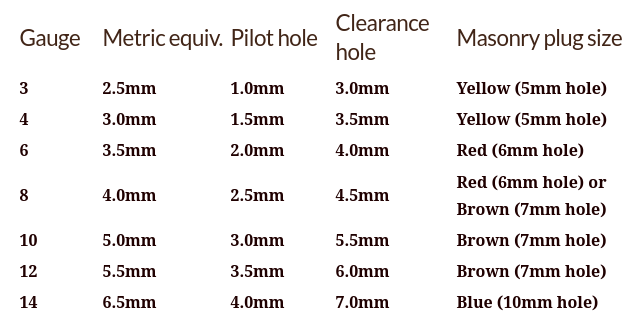

Bore / hole sizes for screws

https://www.mcfeelys.com/drilling_chart

https://littlemachineshop.com/reference/tapdrill.php

Seems consensus is: for easy fit hole, use 4.5 mm hole for #8 screw

Sun Dec 3 12:14:34 AM EST 2023

Submitted ver_0.4 (long, short) to sendcutsend, just used exported dxf file from openscad; we'll see if that works okay...

files here: https://gitlab.com/edgecollective/bike-trailer-dropouts/-/tree/main/v_0.4?ref_type=heads

Tue Dec 26 09:21:43 PM EST 2023

#8-32 tpi machine screws https://www.homedepot.com/p/8-32-x-2-in-Combo-Round-Head-Zinc-Plated-Machine-Screw-4-Pack-803141/204274618

Tue Jan 2 07:36:38 PM EST 2024

Update: want larger screws -- #10 or larger -- and will need to update dropouts

Garden cart idea ... what about using cattle fencing or chicken wire mesh instead of wood?

Cattle fencing is 16 ft x 50 in for $35 -- $0.50 per sq ft

Chicken wire is 4 ft x 100 ft for $100 -- $0.25 per sq ft

16 gauge Welded wire fence is 4 ft x 50 ft for $50 -- $.35 per sq ft

-- and anyway chicken wire is easier to use

Crates used on farms:

Wed Jan 3 06:01:43 PM EST 2024

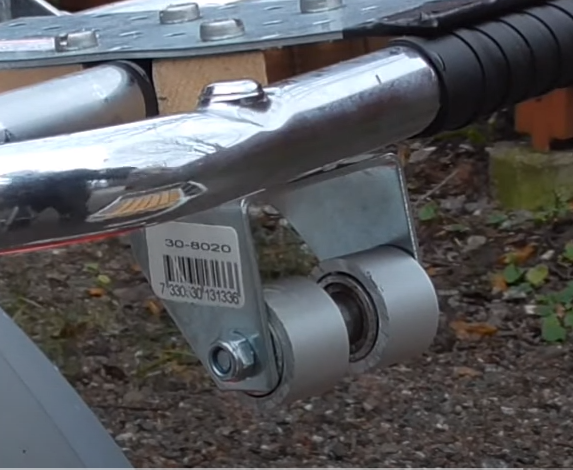

Technique for adding industrial wheels

13" cart or wheelbarrow wheels, 2 for $39, 5/8" bearings

Fri Jan 5 05:50:02 PM EST 2024

Bezier curves in openscad https://benjaminwand.github.io/verbose-cv/projects/bezier_curves.html

Wed Jan 24 08:40:23 PM EST 2024

The u-bolts that fit a 1/2" pipe are here on Amazon

Sat Jan 27 09:35:34 PM EST 2024

Idea: use 'hose clamps' as part of the design -- to hold two pipes together (the 'arm' that connects the trailer to the bike), and also possibly to connect the dropouts to the pipe without the pointy bits of the ubolt sticking out:

20 for $9 on Amazon

Idea: insert something high-friction (used bike tube, etc) under the clamp, to prevent rotation under torque.

Sun Jan 28 01:20:45 PM EST 2024

U-bolts are used extensively in the telecom and utility industries for axial and twist restraint, where exterior-exposed structures with lots of pipe and round tube members exist. Always use lock washers or locking nuts. Don't oversize or undersize the clamping plate. You want a little bit of plate bend during U-bolt tightening. U-bolts are typically A36, HD galvanized. Use U-bolt pairs, as you get beneficial binding action (not counted for in calculation, but real). A reasonable approach is to use 30% of yield stress x net section of threads, and a low friction coefficient (like 0.3). This gives clamping (normal to pipe axis). For torque (twisting), F*d. Provide installation notes on your dwgs regarding range of installation torque. Structural engineers don't usually specify installation torque and threaded fasteners, but this is a good exception.

-- from here

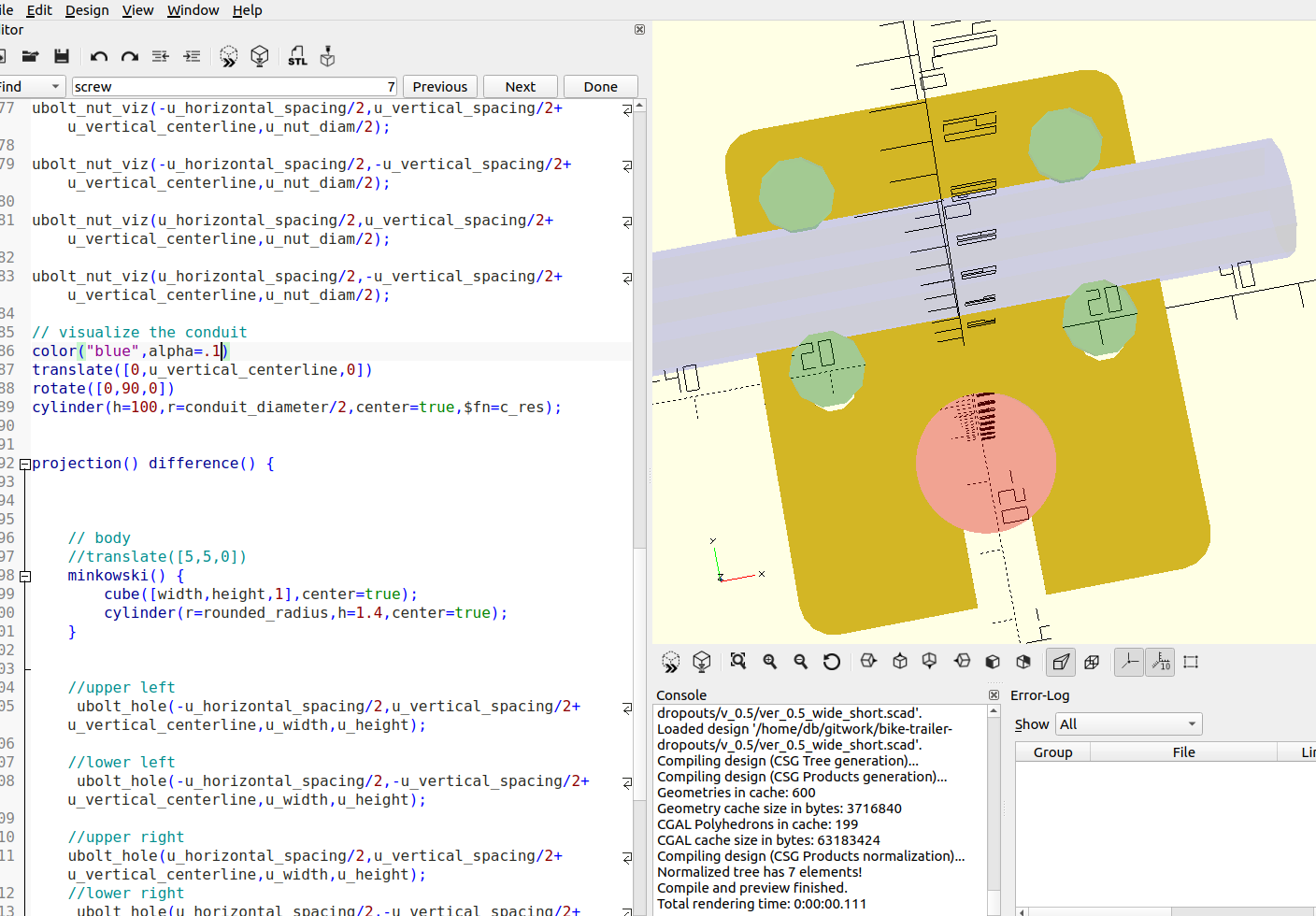

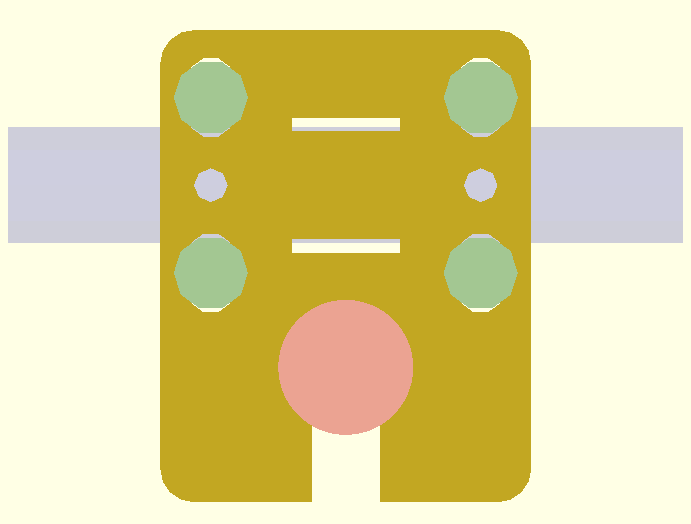

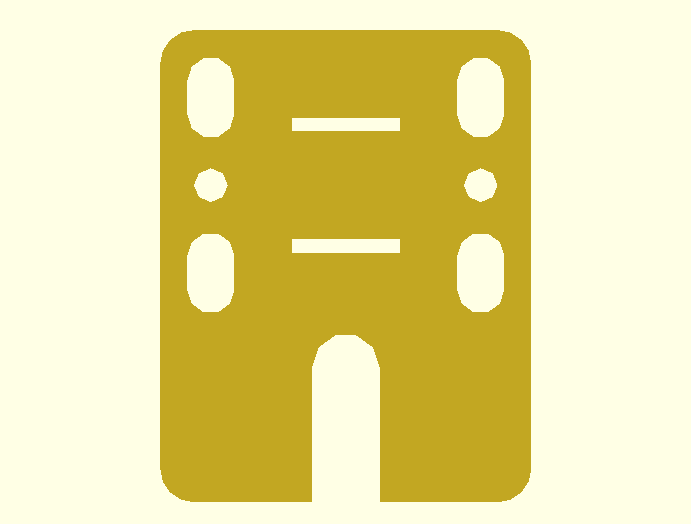

Version 0.5

Version sent to sendcutsend.com on 1/28/23: https://gitlab.com/edgecollective/bike-trailer-dropouts/-/tree/d70551e2d9acb613b94db4331c57283067620711/v_0.5

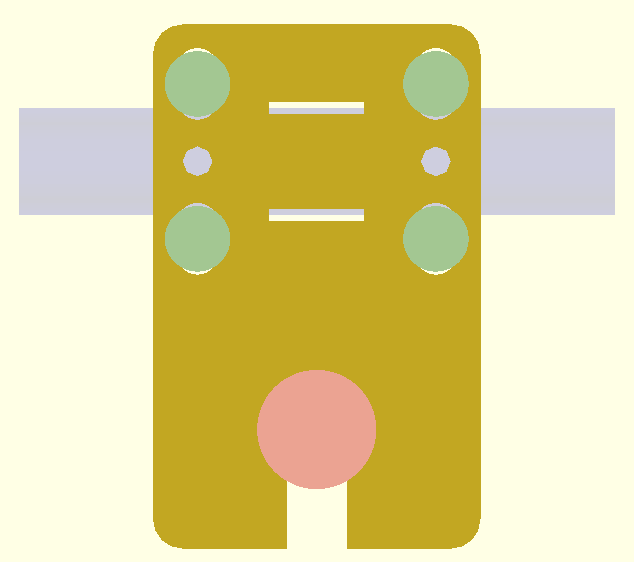

ver 0.5 short

ver 0.5 long