Edge Collective

Crate Carts for Small Farms

Developing an easy-to-assemble cart for transporting standard vegetable containers on small farms, in collaboration with the Young Farmer Network.

Background

Annie Bayer of the Young Farmer Network had the idea for an improved, DIY version of the 'garden carts' that are often used on small farms to transport crates of vegetables. Typical garden carts:

- seem overly expensive (often costing upwards of $500);

- are too small to carry more than one or two crates at a time;

- use a wood-based design that seems unnecessarily heavy;

- have a wheel base that is too narrow to be used on farms with 30" vegetable beds.

Annie proposed a DIY 'crate cart' design that could:

- accommodate four (or, when stacked, 8) crates of the sizes used on small farms (e.g. 24" x 20" x 11" and 23" x 7" x 15");

- be lightweight;

- straddle common 30" vegetable beds; and

- be constructed at low cost from widely-available and/or recycled materials, with a minimum of specialized tools.

We've been working with Annie to develop an initial version of this cart, with an estimated materials cost of approximately $120 (less than 1/3 the cost of a commercial garden cart).

The tools and skills required to build the our current cart design -- i.e., designing with, bending, and cutting metal tubing, as well as the fabrication of small metal parts -- have more general application in farming, including the design and construction of DIY low tunnels, hoop houses, and even mobile chicken coops.

Current design

Our current prototype uses recycled bicycle wheels, electrical conduit, welded wire fencing, and a custom, open-source bicycle wheel dropout design, with an estimated materials cost approximately $120.

The custom wheel dropouts used in this design can be ordered via one of several metal lasercutting services by submitting an open source dropout design file (see below).

The carrying area on the cart is approximately 44" x 54" -- enough to accommodate four 24"x20"x11" crates side-by-side (or eight crates when stacked).

|

|---|

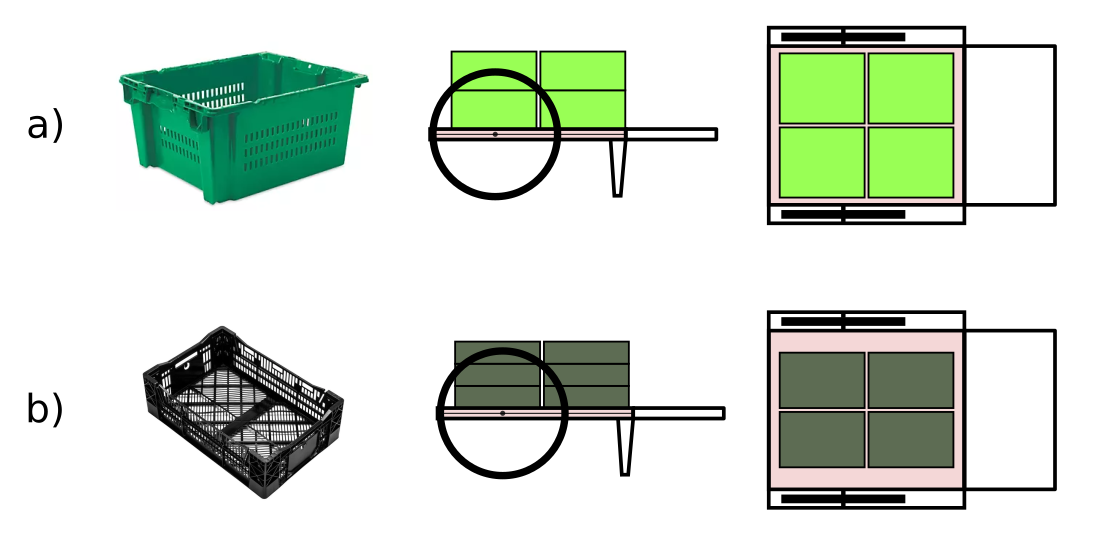

| Footprint on cart of two typical crates used on small farms. Top (a): 24" x 20" x 11" Ventilated Container; and bottom, (b): 23" x 7" x 15" Nursery Crate |

|

|---|

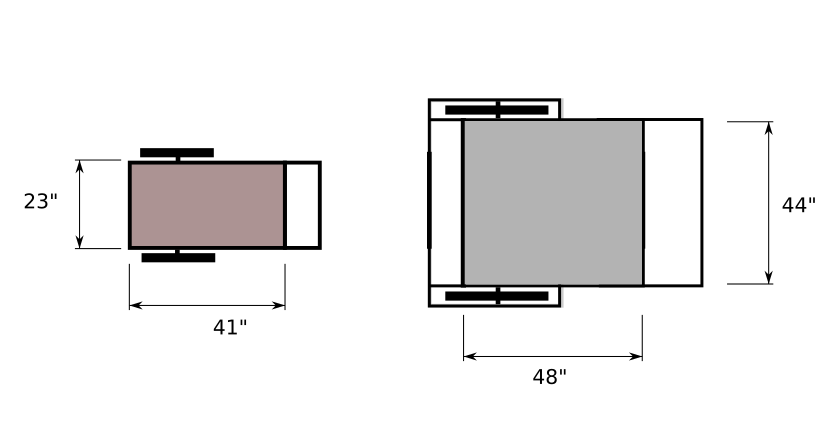

| The crate cart (right) has a significantly larger carrying capacity than a typical 'garden' cart (left) and can be built for less than 1/3 of the cost. |

|

|---|

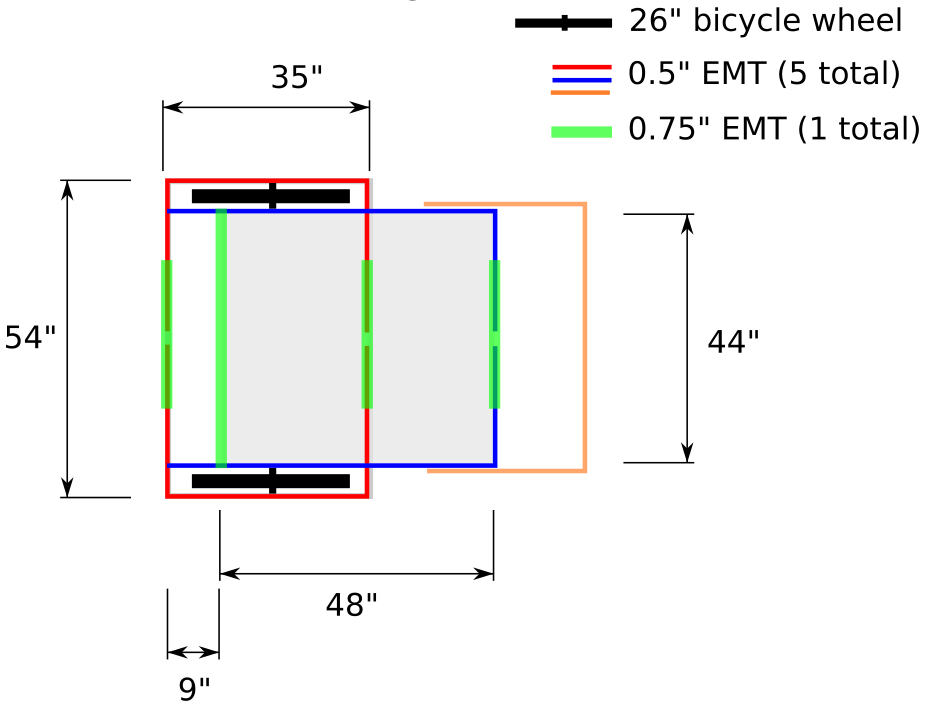

| The current crate cart design uses 5 pieces of 1/2" electrical conduit and one piece of 3/4" conduit, and has a wheel base that can straddle 30" vegetable beds. |

Materials

Recycled bicycle wheels

|

|---|

| This crate cart design accommodates 26" inch or smaller bicycle wheels. The wheels will be attached to dropouts on the cart, just as on a bicycle. |

Electrical conduit

|

|---|

| Five 10-foot lengths of 1/2" metal 'emt' electrical conduit (@ $7 ea from Home Depot) = $35; one 10-foot length of 3/4" conduit is $12. |

U-bolts and screws

|

|---|

| 20 mm u-bolts can be found for $2.50 ea |

|

|---|

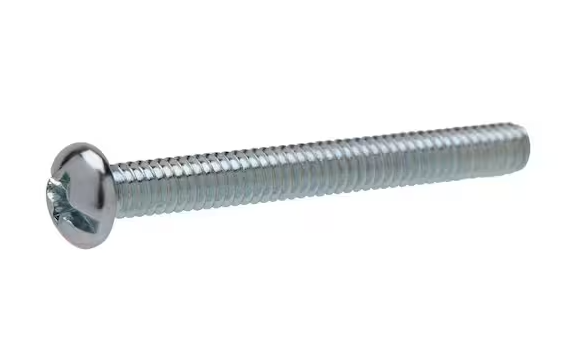

| Eight #10-24 x 2" bolts, with nuts (4 for $1.38 at Home Depot) = $3; Five #10-24 x 2.5" bolts, with nuts (2 for $1.38 at Home Depot) = $5 |

Welded wire

|

|---|

| A 50 ft roll of four-foot welded wire fencing sells for around $72; for our cart design, we only need about $3 worth. |

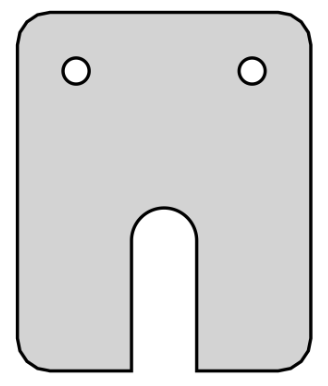

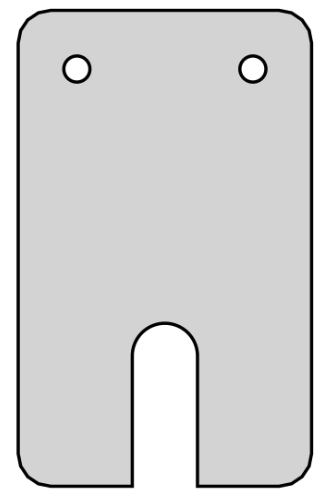

Dropouts to hold the bicycle wheels

The recycled bicycle wheels used on the cart are held on using custom 'dropouts'. While these could be fashioned 'by hand', we have developed an open source design for metal dropouts that can be ordered from one of several online metal lasercutting services (see section on 'dropouts' below).

|

|---|

| Closeup of the custom 'dropouts' for the cart. The design files can be sent to a metal lasercutting service for production (details below). |

|

|---|

| Two 'short' dropouts (@ $3 ea) and two 'long' dropouts (@ $3.30 ea) from sendcutsend.com (see below for design and ordering details) = $13 |

Common tools required

|

|---|

| Phillips-head screwdriver |

|

|---|

| 11/64" drill bit |

|

|---|

| Phillips-head screwdriver |

|

|---|

| Pliers |

Special skills and tools required

The skills and tools associated with constructing the current 'crate cart' prototype also have applications in other aspects of farming.

Designing with, bending, & cutting metal tubing

Electrical conduit is widely used in construction, and is inexpensive to source in most locations. Designing with, bending, and cutting electrical conduit and other metal tubing is often used in the construction of low-cost low tunnels and hoop houses; see, for example, the low tunnel and mobile hoop house designs by Eliot Coleman, and the DIY designs produced by bootstrapfarmer.com.

|

|---|

| Learning to design with, bend, and cut electrical conduit and metal tubing can be useful when building a DIY low tunnel or hoop house, as in this guide by Eliot Coleman. |

|

|---|

| 1/2" conduit pipe bender -- $20 on Amazon, $60 at Home Depot, free if borrowed |

|

|---|

| How to use a pipe bender: https://www.youtube.com/watch?v=r3h97SfQYYI |

|

|---|

| Cutting electrical conduit using an inexpensive hand tool -- via makerpipe.com |

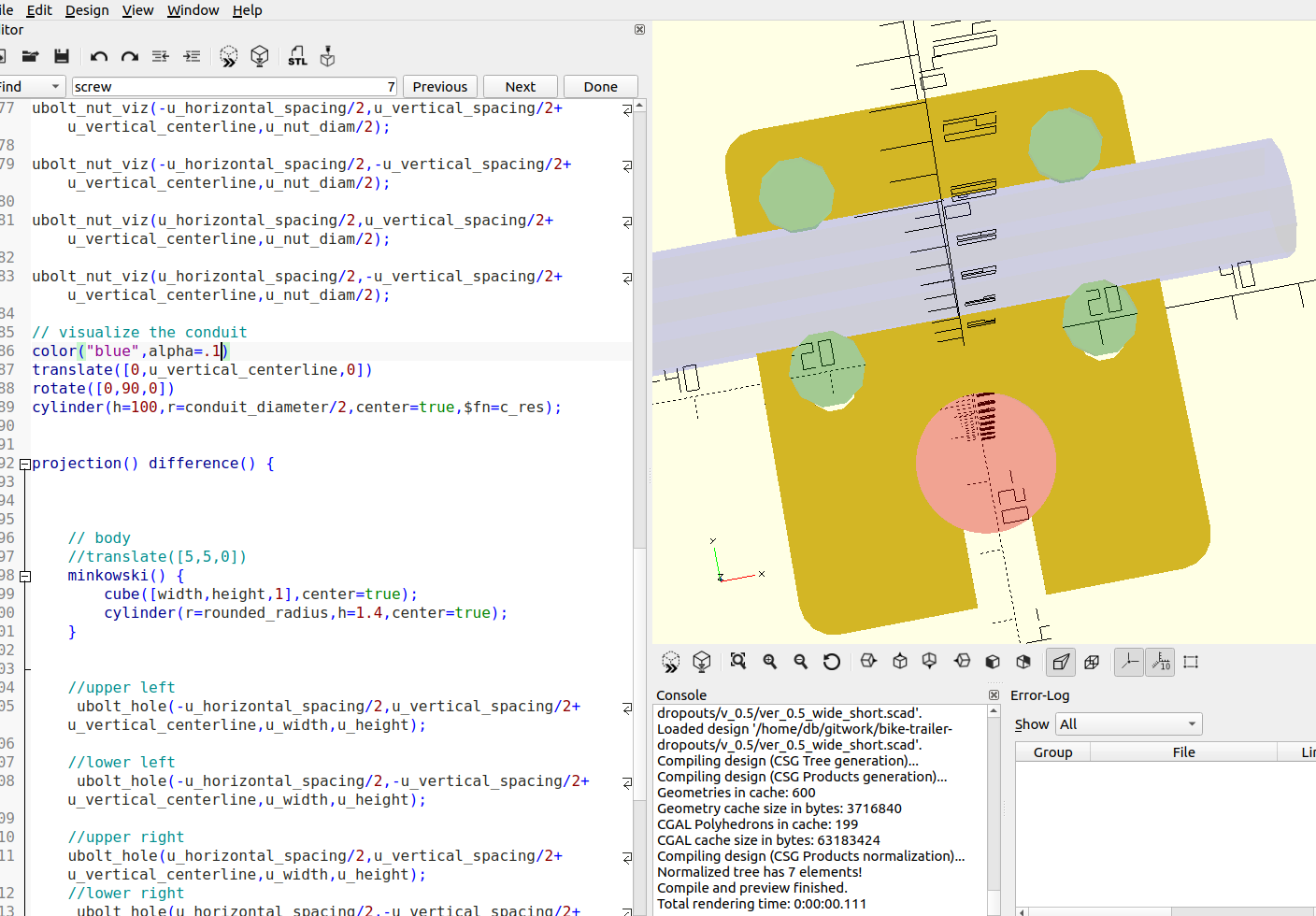

Designing and fabricating 2D laser-cut metal parts

The dropouts in this design are necessary to accommodate the bicycle wheels. While dropouts can be cut from metal sheets 'manually' using an angle grinder or other tools, it is currently inexpensive and convenient to have them fabricated by a metal lasercutting service.

Learning to use a CAD program to design a metal part, and/or ordering a part using an online fabrication service, are skills that can later be used to repair old farm equipment or create parts of new tools. Organizations like L'Atelier Paysan have used lasercut metal parts as part of their tool building and development process for years.

The 'dropouts' necessary for holding the bicycle wheels in place are lasercut steel; they can be ordered by sending the open source design files to an online service such as sendcutsend.com. They were designed using a 2D CAD program called openscad.

|

|---|

| Short dropout. DXF file (for production); SCAD file (for reference or re-design) |

|

|---|

| Long dropout. DXF file (for production); SCAD file (for reference or re-design) |

|

|---|

| Openscad is one of several free and open source CAD programs that can be used to design parts that can later be fabricated by metal lasercutting services. A useful feature of 'parametric design' programs like Openscad is that designs can quickly and easily be scaled or modified in a programmatic fasion to accommodate new design ideas. |

Planned improvements

We're hoping to build some prototypes soon in a workshop setting with farmers in order to get useful feedback and design ideas. Meanwhile, we're working to improve the overall simplicity and structural integrity of the crate design.

Areas we're reviewing include:

Using u-bolts and metal straps instead of drilled holes and screws where possible

We believe we can secure pipe cross-pieces using u-bolts, and avoiding finicky placement and alignment of drilled holes:

Flexible dropout design

We're redesigning the dropouts to allow them to be secured to the cart frame using u-bolts or metal straps as well as screws.

|

|---|

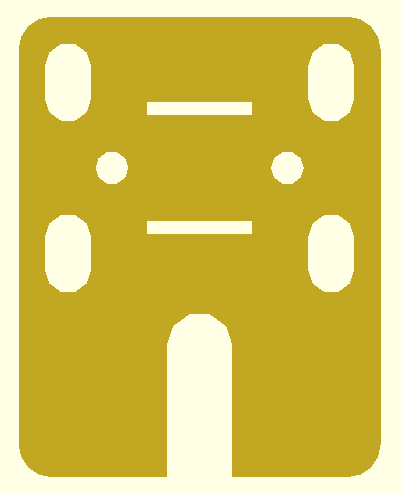

| Version 0.6 of the dropout design. The two smaller holes are for screw-based attachments; the four larger holes are for u-bolts; the two thin horizontal holes are for a metal strap. The relevant openscad file is here |

Redesigning the handle for increased ergonomics

Annie had suggested a handle design that would allow for 'stepping inside' the handle area and easily pulling the cart in that manner. We're looking into ways of using sturdier 3/4" electrical conduit, in a different configuration, in order to enable this.

Misc references and notes

The Bamboo load-centered wheelbarrow

Tue Mar 5 04:56:13 PM EST 2024

Real dimensions of emt conduit via makerpipe

- 3/4" nominal emt is .922" / 24 mm

- 1/2" nominal emt is .706" / 18 mm

U-bolt options:

- .79" / 20 mm inner width u bolts from amazon

- .98" / 25 mm inner width u bolts from amazon

- 1.06" / 27 mm inner width u bolts from amazon

Sun Mar 10 12:12:25 AM EST 2024

Docs for workshop on March 10: